It is general to apply glue or to use heat sealing technique when bonding resins each other. However, there are negative points on these two methods, resulting in not being met the requirement in the objective function. If using a bond technique by surface modified with molecular level, you may see different result and may have more business possibilities.

If facing the above-mentioned problems, please feel free to contact FUKAE KASEI Co., Ltd. at any time! We may help you with new bond method which are one of new bond technique, used with plastic surface modified. We do support you with our best skill and technique.

The users or customers do not need to concern about elution problem because the product is manufactured with our special technique, bonding plastic resin with its geometry characteristic changed at the level of molecule. Therefore, this technique is suitable for the special devices such as microfluidic device or organ-on-a-chip whose design is specialized for the fine geometry.

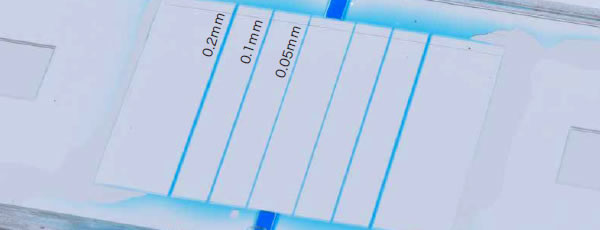

Example) Microfluidic device. The center width of the fluid channel is 50 µm.

Due to its typical character, COP and COC are expected to be utilized in various field such as life science research, food packaging, or optical components. Since the surface modified technique appeared, this enables bonding dissimilar materials. As Fukae Kasei’s performance, we produced Microfluidic device (refer to the above picture) with this technique. In this item, COP having with groove was bonded with plastic board.

We are now positively looking into the bonding possibility in various materials such as PMMA, PC, and more. Please feel free to ask us, FUKAE KASEI about any possibility of bonding using various materials.

CBy using the above-mentioned resin, COP or COC, more possibilities of the device development are now available. In addition, applying our bonding technique may realize a special device development having high optical character and high biological safely.

When performing cell culture, it is clear that cell proliferation and differentiation may be affected by hydrophilicity, functionality, or charge on the surface of the growth such as petri dish. Especially in the case of culturing adherent cell, it is key to culture cell that the growth surface can absorb the cell, and also compatibility of the charge in the cell surface and the growth. Fukae Kasei has also been developing cell culture plate with our original way by searching for various surface modified technique or coating process, then accumulated the know-how on methods of typical technique.