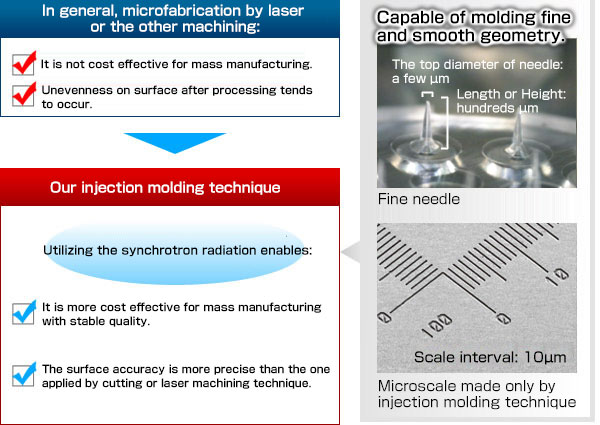

We have already established injection molding technique, which enables fine geometry without laser machining or any other processing.

One specific example is fine needle manufacturing whose top diameter is a few micro meters thinner than a hair (80 µm).

Fine geometry technique provides many possibilities such as mass production with low cost, accuracy and high smoothness on grid lines.

■ Watson

(Grid lines are in the groove form)

■ Other Companies

(Grid lines are convex)

■ Glass

(Grid lines are rough)

Apparently, you may understand that there is a big difference on grid lines. The grid lines of other companies are convex, but WATSON’s are concave. Therefore the cells do not get stuck. In addition, cells are easier to be observed because the grid lines are thinner and smoother than glass slides. It is clear that our novel fine geometry technique realizes productization with excellent quality, such as Cell Counter Plate or Microscale Slide.

Through the combination, it is possible to design microfluidic chip without heat or glue. These techniques will resolve your concerns, such as deformation of the fine geometry by heat, glue leakage into the channels, and the elution of glue. If using microfluidic chip, it is possible to experiment with very small volumes of samples. In addition, we expect its application expanding on drug discovery or medical field.